GRSE Journeyman Recruitment Exam Syllabus 2025, ITI Pass Latest Vacancy 2025

GRSE Journeyman Recruitment Exam Syllabus 2025 :Garden Reach shipbuilders & Engineers Limited (GRSE) की ओर से Recruitment निकली है जो देश के प्रमुख रक्षा Shipyard में से एक प्रमुख Company है। यह Company विभिन्न तरीकों से देश की रक्षा तैयारियों में प्रभावी योगदान दे रही है। GRSE Journeyman Recruitment मे Form भरने वाले Candidates या जो Candidates Form भर दिए है वे सभी Candidates नीचे दिए गए Exam Syllabus को एक बार जरूर पढे I Latest Update पाने के लिए Anil Sir ITI Telegram Group से जरूर जुड़े I

| Recruitment Organization | Garden Reach shipbuilders & Engineers Limited |

| Recruitment Type | Journeyman (Syllabus) |

| Total Posts | 04 |

| Application Mode | Online |

| Application open Date | 05/07/2025 |

| Application Last Date | 04/08/2025 |

| Qualification | 10th+ITI Pass |

| Download Anil Sir ITI App | Click Here |

| Know More | Click Here |

| Join Telegram | Join Telegram |

| Download App | Click Here |

GRSE Recruitment Qualification 2025

| Post Name | Qualification |

| Journeyman (Pipe Fitter) | Matriculation (10 std. pass) with NAC / NTC in Pipe Fitter / Plumbing trades |

| Journeyman (Painter) | Matriculation (10 std. pass) with NAC / NTC in Painter (General) / Painter (Marine) / Industrial Painter trade |

| Journeyman (Computer Operator) | Matriculation (10 std. pass) with NAC / NTC in COPA / PASAA / Information Technology/ Data Base System Assistant/ Desktop Publishing Operator trades |

GRSE Journeyman Selection Process 2025

- Written Test

- Shortlist

- Practical (Trade) test

- Document verification

| Exam Pattern | OMR Based |

| Question Paper type | Multiple Choice Questions |

| Exam Centre | Kolkata & Ranchi |

| Duration of Written Test | 2 Hours |

| Written Marks | 100 marks |

| Exam Language | English and Hindi |

GRSE Journeyman Exam Pattern 2025

| Part | Type of questions | Marks |

| Part-I | Subject (trade) related questions as per relevant trade syllabus uploaded in GRSE website | 80 marks |

| Part-II | General Knowledge, General Aptitude, Reasoning, Mental Ability, Numerical Ability | 20 marks |

| Total | 100 marks |

GRSE Journeyman Exam Qualifying Marks 2025

- Duration of Written Test – 02 Hours.

- Question paper type: Objective type with Multiple Choice Questions.

- Qualifying marks: Overall 40% marks in written test (out of 100 marks)

GRSE Journeyman Exam Important Notice 2025

- Practical (Trade) test will be of qualifying in nature.

- Practical (Trade) test will be based on the Qualitative requirement for the notified posts which will be uploaded in the website.

- Document verification of the shortlisted candidates will be carried out before the practical test to check whether they are meeting the eligibility criteria for the applied post as per the advertisement.

- Only those candidates who will clear the document verification stage will be allowed to appear in the practical test.

- The candidates qualified in Practical test will only be considered in the final merit list to be drawn on the basis of marks in written test.

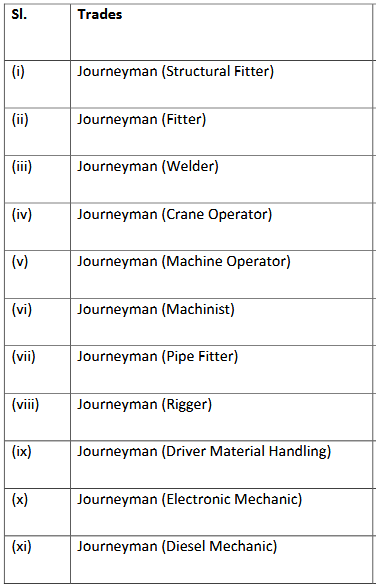

GRSE Journeyman Syllabus 2025

GRSE JOURNEYMAN (FITTER) Syllabus 2025

- I. General Fitter Trades

- Linear Measurements

- Units

- Dividers

- Calipers

- Hermaphrodite calipers

- Centre punch

- Dot punch

- Prick punch

- Description and uses of different types of hammers

- ‘V’ Blocks (description, use, care)

- Marking off table

- Measuring Standards

- English Units

- Metric Units

- Angular measurements

- Bench Vice

- Construction

- Types

- Uses

- Care & maintenance

- Vice clamps

- Hacksaw Frames and Blades

- Specification

- Description

- Types

- Uses

- Method of using hacksaws

- Files

- Specifications

- Description

- Materials

- Grades

- Cuts

- File elements

- Uses

- Types of files

- Care and maintenance

- Marking off and Layout Tools

- Dividers

- Scribing block (description, classification, material, care & maintenance)

- Try square (description, uses, cares)

- Ordinary depth gauge (description, uses, cares)

- Protractor (description, uses, cares)

- Cold Chisels

- Materials

- Types

- Cutting angles

- Uses

- Care & maintenance

- Marking Media

- Marking blue

- Prussian blue

- Red lead

- Chalk

- Special application

- Description

- Scribing Block

- Use

- Care and maintenance

- Surface Plate and Auxiliary Marking Equipment

- ‘V’ block

- Angle plates

- Parallel block

- Description

- Types

- Uses

- Accuracy

- Care and maintenance

- Physical Properties of Engineering Metal

- Colour

- Weight

- Structure

- Conductivity

- Magnetic properties

- Fusibility

- Specific gravity

- Mechanical Properties

- Ductility

- Malleability

- Hardness

- Brittleness

- Toughness

- Tenacity

- Elasticity

- Power Saw

- Band saw

- Circular saw machines used for metal cutting

- Micrometer

- Outside and Inside Micrometer (principle, constructional features, parts graduation, reading, use, care)

- Micrometer depth gauge (parts, graduation, reading, use, care)

- Digital micrometer

- Vernier Calipers

- Principle

- Construction

- Graduations

- Reading

- Use and care

- Vernier bevel protractor (construction, graduations, reading, use, care)

- Dial Vernier Caliper

- Digital Vernier caliper

- Vernier Height Gauge

- Material construction

- Parts

- Graduations (English & Metric)

- Uses

- Care and maintenance

- Drilling Processes

- Common types (bench type, pillar type, radial type)

- Gang and multiple drilling machine

- Determination of tap drill size

- Drill

- Material

- Types (Taper shank, straight shank)

- Parts (shank body, flute, cutting edge)

- Drill angle (cutting angle for different materials)

- Cutting speed feed

- R.P.M. for different materials

- Drill holding devices (material, construction, uses)

- Tap Wrench

- Material

- Parts

- Types (solid & adjustable types)

- Uses

- Removal of broken tap

- Studs (tap stud extractor)

- Dies

- British standard

- Metric and BIS standard

- Material

- Parts

- Types

- Method of using dies

- Die stock (material, parts, uses)

- Drill Troubles

- Causes and remedy

- Equality of lips

- Correct clearance

- Dead centre

- Length of lips

- Drill kinds (Fraction, metric, letters and numbers)

- Grinding of drill

- Grinding Wheel

- Abrasive

- Grade structures

- Bond

- Specification

- Use

- Mounting and dressing

- Selection of grinding wheels

- Bench grinder parts and use

- Gauges

- Introduction

- Necessity

- Types

- Limit gauge (Ring gauge, snap gauge, plug gauge, description, uses)

- Gauge-types (feeler, screw, pitch, radius, wire gauge)

- Interchangeability

- Necessity in Engineering field

- Definition

- BIS (Definition, types of limit, terminology of limits and fits – basic size, actual size, deviation, high and low limit, zero line, tolerance zone)

- Different standard systems of fits and limits (British standard system, BIS system)

- Method of expressing tolerance as per BIS Fits (Definition, types, description of each with sketch)

- Vernier Height Gauge (Repeated, but with more detail here)

- Material construction

- Parts

- Graduations (English & Metric)

- Uses

- Care and maintenance

- Pig Iron

- Types

- Properties

- Uses

- Cast Iron

- Types

- Properties

- Uses

- Wrought Iron

- Properties

- Uses

- Steel

- Plain carbon steels

- Types

- Properties

- Uses

- Non-Ferrous Metals (Copper, Aluminum, Tin, Lead, Zinc)

- Properties

- Uses

- Simple Scraper

- Flat

- Half round

- Triangular

- Hook scraper

- Uses

- Blue matching of scraped surfaces (flat and curved bearing surfaces)

- Testing scraped surfaces (ordinary surfaces without a master plate)

- Vernier Micrometer (Repeated, but with more detail here)

- Material

- Parts

- Graduation

- Use

- Care and maintenance

- Calibration of measuring instruments

- Mechanical Fasteners

- Introduction

- Uses

- Screw Thread Micrometer

- Construction

- Graduation

- Use

- Dial Test Indicator

- Construction

- Parts

- Material

- Graduation

- Method of use

- Care and maintenance

- Digital dial indicator

- Comparators (measurement of quality in the cylinder bores)

- Lathe Operation Safety Precautions

- Safety precautions to be observed while working on a lathe

- Lathe specifications

- Constructional features

- Lathe main parts descriptions (bed, head stock, carriage, tail stock, feeding and thread cutting mechanisms)

- Holding of job between centres

- Works with catch plate, dog

- Simple description of a facing and roughing tool and their applications

- Lathe Cutting Tools

- Nomenclature of single point & multipoint cutting tools

- Tool selection based on different requirements and necessity of correct grinding

- Solid and tipped tools

- Throw away type tools

- Cutting speed and feed

- Comparison for H.S.S., carbide tools

- Use of coolants and lubricants

- Chucks and Chucking

- Independent four-jaw chuck

- Reversible features of jaws

- Back plate

- Method of clearing the thread of the chuck-mounting and dismounting

- Chucks

- Chucking true

- Face plate

- Drilling (method of holding drills in the tail stock, boring tools and enlargement of holes)

- General Turning Operations

- Parallel or straight turning

- Stepped turning

- Grooving

- Shape of tools for the above operations

- Appropriate method of holding the tool on tool post or tool rest

- Knurling

- Tools description

- Grade

- Uses

- Speed and feed

- Coolant for knurling

- Speed, feed calculation

- Taper

- Definition

- Use

- Method of expressing tapers

- Standard tapers-taper

- Calculations Morse taper

- Screw Thread

- Definition

- Uses and application

- Square, worm, buttress, acme (non-standard-screw threads)

- Principle of cutting screw thread in centre lathe

- Principle of chasing the screw thread

- Use of centre gauge

- Setting tool for cutting internal and external threads

- Use of screw pitch gauge for checking the screw thread

- II. Sheet Metal Workshop

- Safety Precautions

- Safety precautions to be observed in a sheet metal workshop

- Sheet and sizes

- Commercial sizes and various types of metal sheets

- Coated sheets and their uses as per BIS specifications

- Shearing machine (description, parts, uses)

- Marking and Measuring Tools (Sheet Metal)

- Wing compass

- Tin man’s square tools

- Snips (types, uses)

- Tin man’s hammers and mallets (type-sheet metal tools, types, specifications, uses)

- Trammel (description, parts, uses)

- Hand Grooves

- Specifications

- Uses

- Sheet and Wire Gauge

- Stakes

- Bench types

- Parts

- Uses

- Metal Joints

- Various types

- Selection and application

- Tolerance for various joints

- Selection & application

- Wired edges

- Solder and Soldering

- Introduction

- Types of solder and flux

- Composition of various types of solders

- Heating media of soldering iron

- Method of soldering

- Selection and application-joints

- Hard solder (introduction, types, method of brazing)

- Rivets

- Various shapes and forms of heads

- Importance of correct head size

- Tin man’s rivets (types, sizes, selection for various works)

- Riveting tools (dolly snaps description, uses)

- Method of riveting

- Spacing of rivets

- Flash riveting (use of correct tools)

- Compare hot and cold riveting

- Welding Shop Safety

- Importance of safety and general precautions observed in a welding shop

- Precautions in electric and gas welding (Before, during, after)

- Introduction to safety equipment and their uses

- Machines and accessories (welding transformer, welding generators)

- Welding Hand Tools

- Hammers

- Welding description

- Types and uses

- Description

- Principle

- Method of operating

- Carbon dioxide welding

- Welding Equipment

- H.P. welding equipment (description, principle, method of operating)

- L.P. welding equipment (description, principle, method of operating)

- Types of Joints

- Butt and fillet as per BIS SP: 46-1988 specifications

- Gases and Gas Cylinder

- Description

- Kinds

- Main difference and uses

- ARC Welding Machines

- Setting up parameters

- Selection of Welding electrodes

- Oxygen Acetylene Cutting

- Machine description

- Parts

- Uses

- Method of handling

- Cutting torch (description, parts, function, uses)

- Reamer

- Material

- Types (Hand and machine reamer)

- Kinds

- Parts and their uses

- Determining hole size (or reaming)

- Reaming procedure

- Screw Threads

- Terminology

- Parts

- Types and their uses

- Screw pitch gauge (material parts, uses)

- Taps British standard (B.S.W., B.S.F., B.A. & B.S.P.) and metric /BIS (coarse and fine)

- III. Engineering Drawing

- Introduction to Engineering Drawing and Drawing Instruments

- Conventions

- Sizes and Layout of Drawing Sheets

- Title Block

- Position and content

- Drawing Instrument

- Lines

- Types and applications in drawing

- Free Hand Drawing

- Geometrical figures and blocks with dimension

- Transferring measurement from the given object to the freehand sketches

- Hand tools and measuring tools

- Drawing of Geometrical Figures

- Angle

- Triangle

- Circle

- Rectangle

- Square

- Parallelogram

- Lettering & Numbering

- Single Stroke

- Dimensioning

- Position of dimensioning (Unidirectional, Aligned)

- Types of arrowhead

- Leader line with text

- Symbolic Representation

- Different symbols used in the related trades

- Concept and Reading of Drawing

- Concept of Axes Plane and Quadrant

- Concept of Orthographic and Isometric Projections

- Method of First Angle and Third Angle Projections

- Definition and difference

- IV. Workshop Calculation & Science

- Unit

- Classification of unit system

- Fundamental and Derived units (F.P.S, C.G.S, M.K.S and SI units)

- Measurement units and conversion

- Factors, HCF, LCM and Problems

- Fractions

- Addition, subtraction, multiplication & division

- Decimal fractions (addition, subtraction, multiplication & division)

- Square Root

- Ratio and Proportions

- Percentage

- Square and square root

- Applications of Pythagoras Theorem

- Related problems

- Ratio and Proportion

- Direct and indirect proportions

- Percentage

- Changing percentage to decimal and fraction

- Mass, Weight, Volume and Density

- Mass, volume, density, weight and specific gravity

- Related problems for mass, volume, density, weight and specific gravity

- Speed and Velocity

- Work, Power and Energy

- Work, power, energy, HP, IHP, BHP and efficiency

- Heat & Temperature and Pressure

- Concept of heat and temperature

- Effects of heat

- Difference between heat and temperature

- Boiling point & melting point of different metals and non-metals

- Concept of pressure (Units of pressure, atmospheric pressure, absolute pressure, gauge pressure and gauges used for measuring pressure)

- Basic Electricity

- Introduction and uses of electricity

- Electric current (AC, DC and their comparison)

- Voltage

- Resistance and their units

- Mensuration

- Area and perimeter of square, rectangle and parallelogram

- Area and perimeter of Triangles

- Area and perimeter of circle, semi-circle, circular ring, sector of circle, hexagon and ellipse

- Surface area and volume of solids (cube, cuboid, cylinder, sphere and hollow cylinder)

- Finding the lateral surface area, total surface area and capacity in litres of hexagonal, conical and cylindrical shaped vessels

- Levers and Simple Machines

- Simple machines (Effort and load, mechanical advantage, velocity ratio, efficiency of machine, relationship between efficiency, velocity ratio and mechanical advantage)

- Trigonometry

| GRSE Journeyman All Syllabus | Click Here |

| Apply Now | Click Here |

| Notification | Click Here |

| Apply Railway Apprentice | Click Here |

| Join Telegram | Click Here |

| Join WhatsApp | Click Here |

grse journeyman recruitment 2025, grse journeyman syllabus exam pattern 2025, grse journeyman exam syllabus and pattern 2025, grse journey man new recruitment 2025, journeyman recruitment 2025, grse technician verious post recruitment 2025, grse recruitment 2025, grse journeyman 2025, grse iti recruitment 2025, grse journeyman job 2025, grse recruitment 2025 apply online, grse journeyman iti vacancy 2025, grse journeyman vacancy 2025, grse recruitment apply online 2025, grse new vacancy syllabus 2025